Cold weather slashes range in electric vehicles because cabin and battery heating become major loads. Traditional positive-temperature-coefficient (PTC) resistive heaters convert electricity to heat at a 1:1 ratio, often drawing 3–7 kW and cutting highway range by 20–40% in subfreezing conditions. Automotive heat pumps move heat instead of making it, routinely delivering two to three units of cabin heat per unit of electrical input at mild-cold temperatures. Recent models from Tesla, Hyundai/Kia, VW, GM, Nissan, and others integrate heat pumps with battery thermal management, raising winter efficiency. Independent winter tests in 2024 show that well-tuned heat pump systems materially reduce cold-weather range loss compared with resistive-only approaches.

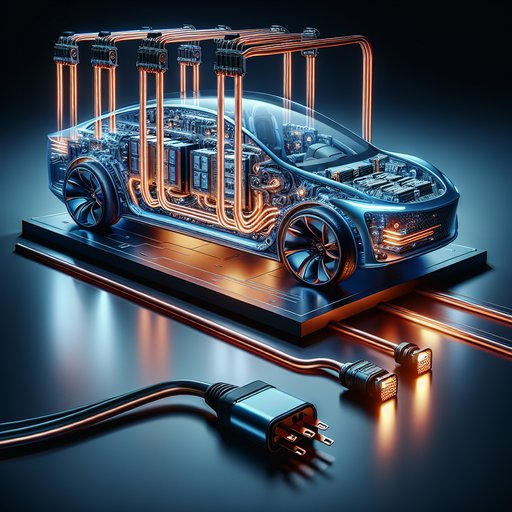

Raising an EV’s DC bus from ~400 V to ~800 V halves current for the same power, slashing I²R losses, shrinking copper mass, and enabling higher fast‑charge rates on 1,000‑V hardware. Automakers from Porsche and Hyundai–Kia to Lucid, GM and Tesla now deploy 800‑V subsystems, paired increasingly with 1,200‑V silicon‑carbide (SiC) switches. The shift isn’t free: insulation, creepage/clearance, EMI, and thermal control grow more demanding, and charging speed remains bounded by cell chemistry and thermal limits. Still, with 350‑kW chargers proliferating and newer vehicles managing 10–80% charges in under 20 minutes, 800‑V is becoming a mainstream tool to improve efficiency, performance, and packaging.

Gasoline retail matured over a century around high-throughput pumps and simple, redundant equipment. Public EV charging is compressing that buildout into a decade, with tighter power, software, and land-use constraints. Comparing the two reveals why EV sites look and perform differently: uptime is defined by networked electronics as much as hardware, charging speeds are capped by vehicle acceptance and taper, multi‑megawatt grid connections are non-trivial, and dwell times reshape real estate. Recent policy—NEVI’s 97% uptime rule, state reporting, and SAE J3400 (NACS) adoption—shows reliability and interoperability becoming central as DC fast charging moves from pilot to utility-grade service.

Trump can’t stop America from building cheap EVs, and that is less a story about one politician than about how durable institutions outlast charismatic politics [4]. The real democratic test is whether complex, technical transformations are guided by expertise or buffeted by applause lines. Directly elected leaders are often selected for their ability to electrify rallies, not to design procurement rules, steward trade frameworks, or run evidence-based regulatory processes. The EV race exposes a broader democratic fault: when selection rewards emotional resonance over demonstrated competence, populism flourishes, policymaking lurches, and yet the machinery of law, trade, and regulation keeps grinding forward—if we let it [4].