They arrived as sparks behind safety fences—obedient arms doing the dirty work nobody missed—and then kept learning. From the first programmable manipulators to today’s camera‑guided, AI‑assisted cobots, industrial robots have evolved from brute repetition to adaptable collaborators. In their rise is the story of global manufacturing’s last half‑century: the consolidation of car plants, the proliferation of electronics assembly, the tug‑of‑war between offshoring and reshoring, and a new calculus for what work stays human. The robots have not taken over so much as settled in, recalibrating prices, expectations, and borders. Their next act, informed by perception and simulation, will test whether factories can become as reconfigurable as software—able to pivot with demand spikes, climate constraints, and geopolitical shocks. What began as a cage for machines now looks more like a stage where people and robots rehearse a future of shared precision.

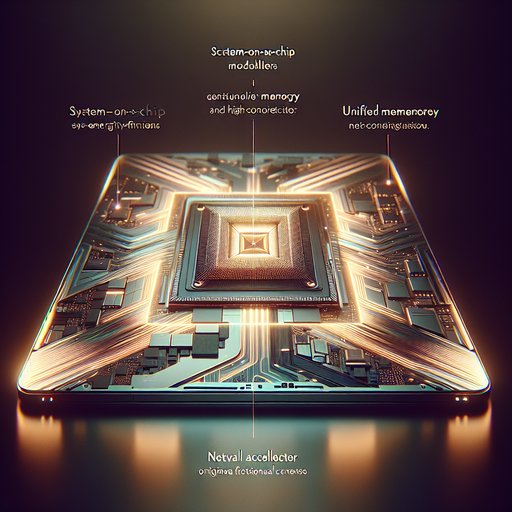

AI’s recent leaps didn’t spring from software alone; they were coaxed from silicon that stopped pretending to be a general-purpose computer. Graphics processors learned a new grammar for linear algebra. Data centers stitched accelerators together like organ systems. And now neuromorphic hardware—machines that compute with spikes and timing instead of clocks and frames—edges from research into prototypes that see, react, and conserve power with an animal’s thrift. The result is not just faster models, but a change in where intelligence lives: less in cloud fortresses and more in the hands, wheels, wings, and sensors that encounter the physical world first.

The new creative handshake happens in the half‑light of screens: a human sketches intent in a sentence, and a model replies with images, copy, code, or melody. What began as a research curiosity has slipped into daily workflows, remapping how ideas move from brief to product and how businesses price speed itself. Generative AI is not just a tool; it behaves like a studio assistant with infinite stamina, an analyst who reads everything, a sales rep who never sleeps. Its rise is neither sudden nor simple. It echoes decades of experiments in machine creativity, now amplified by transformers and cheap cloud muscle, and it forces a negotiation—between imagination and automation, originality and scale, authorship and efficiency—that will define the next economy.

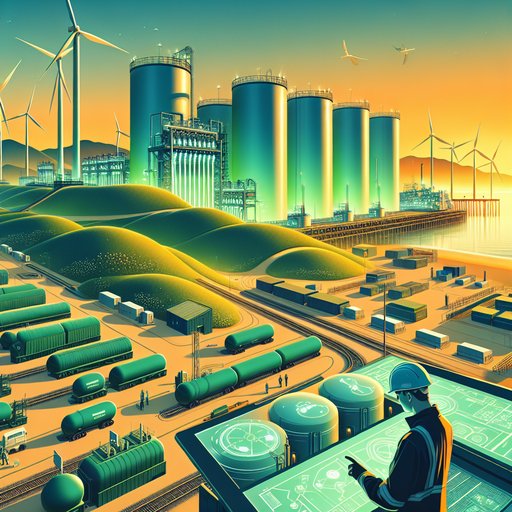

Weather grows stranger, labor scarcer, soils tighter with debt and compaction. Yet in fields where diesel once set the tempo, quiet electric motors and lines of code begin to carry the tune. Autonomous farm robots and AI-driven precision agriculture don’t promise a silver bullet; they offer something more pragmatic and radical at once—attention. Plant by plant, patch by patch, these systems measure, decide, and act with a granularity that was once impossible, turning brute-force cultivation into a choreography of restraint. If food security is the ability to produce enough, reliably, in the teeth of climate and market shocks, then machines that see every leaf and remember every storm are less a sci‑fi flourish than a new layer of agronomy. The opportunity is to grow smarter, not simply bigger: to harvest resilience from information.