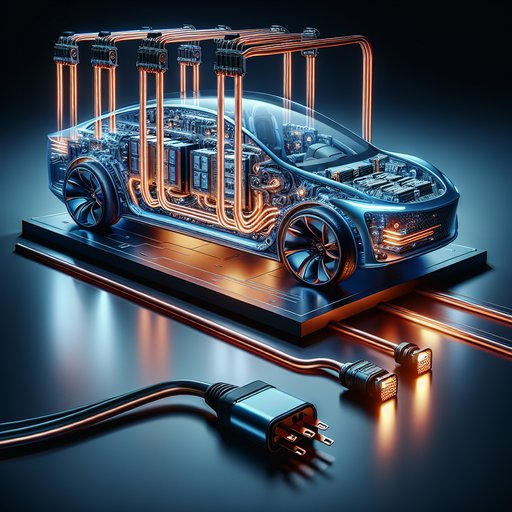

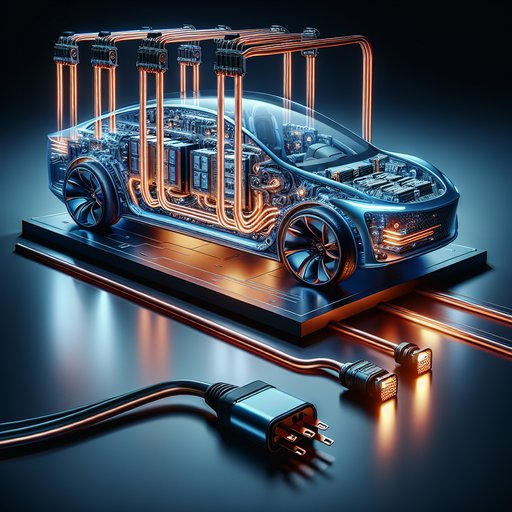

Raising an EV’s DC bus from ~400 V to ~800 V halves current for the same power, slashing I²R losses, shrinking copper mass, and enabling higher fast‑charge rates on 1,000‑V hardware. Automakers from Porsche and Hyundai–Kia to Lucid, GM and Tesla now deploy 800‑V subsystems, paired increasingly with 1,200‑V silicon‑carbide (SiC) switches. The shift isn’t free: insulation, creepage/clearance, EMI, and thermal control grow more demanding, and charging speed remains bounded by cell chemistry and thermal limits. Still, with 350‑kW chargers proliferating and newer vehicles managing 10–80% charges in under 20 minutes, 800‑V is becoming a mainstream tool to improve efficiency, performance, and packaging.

Read more …