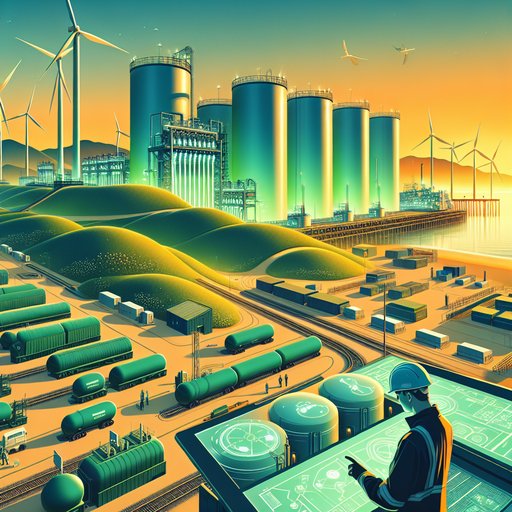

Green hydrogen—produced by splitting water with renewable electricity—has moved from concept to concrete demonstrations as countries seek solutions for long-duration energy storage and zero-emission transport. Pilot projects on islands, in refineries, at ports, and along freight corridors now show how hydrogen can absorb surplus wind and solar, stabilize grids, and fuel heavy-duty vehicles where batteries struggle. Yet the same projects also expose the hard engineering and market realities of moving and storing a tiny molecule at scale: compression, safety codes, station utilization, pipeline materials, and dependable supply. The path forward is neither a simple extension of today’s gas systems nor a copy-paste of the electric vehicle rollout. It is a coordinated build-out that links renewable generation, electrolyzers, storage caverns, pipelines or carriers, and end-use fleets—supported by standards and business models that make each link investable.

The relevance of green hydrogen rises with every percentage point of wind and solar added to power systems. Variable renewables are excellent for cutting emissions, but they heighten the need for flexible, long-duration storage and for decarbonizing sectors beyond the grid. Hydrogen can convert surplus electricity into a storable molecule, later reconverted to power or used directly as a fuel, thus complementing batteries rather than competing with them. In transport, hydrogen’s fast refueling and high energy density make it a candidate for buses, heavy trucks, trains, and some maritime applications where mass and downtime matter.

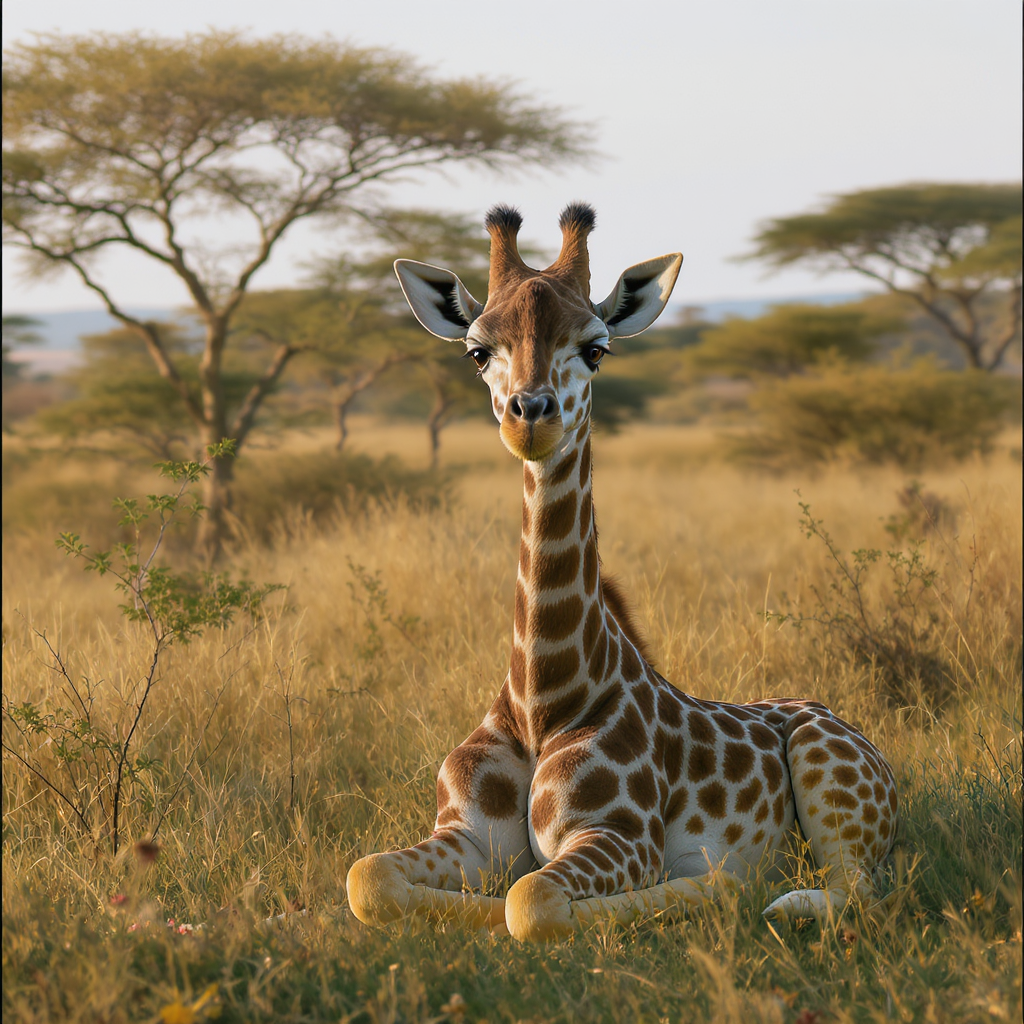

Pilot storage projects show the concept in action. In Japan, the Fukushima Hydrogen Energy Research Field couples a large solar array to megawatt-scale electrolyzers to produce hydrogen when power is plentiful, then supplies industry and mobility uses. In Germany, early power‑to‑gas plants like Energiepark Mainz demonstrated that grid-connected electrolyzers can provide balancing services while producing hydrogen for local demand. On Scotland’s Orkney Islands, surplus wind and tidal power is converted to hydrogen for heat and maritime applications, turning curtailment into useful energy and building local skills for handling and safety.

Utility-scale storage is beginning to take shape underground. The ACES Delta project in Utah combines renewable-powered electrolyzers with salt cavern storage and a nearby power plant capable of firing a hydrogen blend, offering seasonal shifting and fast ramping to back up the grid. In the Netherlands, Gasunie’s HyStock is developing hydrogen storage linked to future industrial and mobility demand, anticipating regional “hydrogen valleys.” These projects test everything from cavern integrity and cushion gas requirements to dispatch strategies that value hydrogen as an insurance policy against low-wind periods. On the transport side, demonstrations span road, rail, and ports.

European cities have operated fuel-cell buses for years under joint procurement programs, building maintenance know-how and station experience at 350 bar. In Switzerland, fleet trials with hydrogen trucks have validated reliable daily operations on fixed routes with back-to-base refueling, while Germany and Japan have built national refueling networks to support early adopters. Hydrogen trains entered passenger service in Germany with fuel-cell multiple units replacing diesel on non-electrified lines, illustrating a niche where batteries or catenary extensions are costly. At U.S.

ports, drayage truck pilots show promise for high-utilization, short-range duty cycles where centralized fueling can be assured. Refueling and logistics are where lessons get specific. Early stations reveal that reliable supply matters as much as nameplate capacity; downtime erodes user confidence and asset economics. Developers test different supply modes—on-site electrolysis, gaseous deliveries by tube trailer, or liquid hydrogen—to match station throughput and cost, while choosing 350 bar for heavy vehicles and 700 bar for light-duty to balance range and compression work.

California’s experience highlights the need for robust upstream production and redundancy to avoid station outages, and for clustering demand so utilization rises above the low levels that strain economics. Successful pilots sequence fleets and stations together, guaranteeing an initial load that allows costs per kilogram to fall. Moving hydrogen at scale raises infrastructure questions that pilots help answer. Blending trials such as HyDeploy in the United Kingdom and GRHYD in France have tested injecting limited volumes of hydrogen into existing gas distribution networks, informing appliance compatibility and safety procedures.

Most analyses find blending can help early offtake but is not a long-term decarbonization strategy for end users; dedicated hydrogen pipelines—new builds or repurposed transmission lines—become more compelling at higher volumes. Europe’s proposed Hydrogen Backbone maps corridors linking industrial clusters and ports, while material testing and monitoring aim to manage issues like embrittlement and leakage. Parallel work on standards for purity, metering, and guarantees of origin allows molecules to be traded with confidence across borders. Economics and supply chains are pivotal.

Electrolyzer costs have fallen as manufacturing scales for alkaline and PEM technologies, but total hydrogen cost is still driven by electricity price and utilization; cheap, high-capacity‑factor renewables and flexible operating profiles are essential. PEM electrolyzers enable dynamic response but rely on scarce iridium, spurring efforts to reduce loading and diversify to alkaline and solid oxide designs. Water demand is modest relative to other industrial uses but still requires siting in regions with sustainable supply or pairing with water recycling; desalination adds cost and energy use that must be factored in coastal projects. Hydrogen’s indirect climate effects via atmospheric chemistry make leak minimization important, reinforcing the need for detection, tight fittings, and best practices.

The most convincing pilots share a common DNA: they anchor hydrogen in specific, high-value uses and cluster the entire chain in one geography. Fertilizer plants, refineries, steelworks, ports, and logistics hubs can absorb large, steady volumes, justifying dedicated production, storage, and pipelines or short-haul deliveries. Maritime and aviation ecosystems are testing hydrogen-derived fuels such as ammonia or synthetic kerosene for bunkering and e-fuel production, while demonstrator flights and vessels inform safety and handling. By co-locating supply and demand, these projects reduce transport costs, raise utilization, and build a trained workforce that can expand the system step by step.

What do these efforts add up to for energy storage and clean transport? First, green hydrogen is best used where its unique attributes—long-duration storage, fast refueling, high energy density—solve problems that batteries and direct electrification cannot. Second, reliability, standards, and market design are as important as megawatts of electrolyzers; without dependable supply and clear carbon accounting, demand will stall. Third, a staged approach—starting with industrial clusters and heavy-duty fleets, building salt cavern storage, and linking clusters with backbone pipelines—offers a pragmatic path to scale.

The pilot era has done its job by exposing weak links; the next phase is about integrating them into bankable systems. With careful planning and honest cost signals, green hydrogen can complement electrification to deliver resilient, low-carbon energy. Scaling will depend on abundant renewables, smart siting, disciplined leakage control, and patient capital aligned with long-lived infrastructure. The prize is a system that can store seasonal energy, decarbonize heavy transport, and supply clean molecules to industry, all while strengthening energy security.

If pilots continue to inform design choices and policy stays focused on real-world performance, the hydrogen backbone can grow from demonstration to dependable service.