They arrived as sparks behind safety fences—obedient arms doing the dirty work nobody missed—and then kept learning. From the first programmable manipulators to today’s camera‑guided, AI‑assisted cobots, industrial robots have evolved from brute repetition to adaptable collaborators. In their rise is the story of global manufacturing’s last half‑century: the consolidation of car plants, the proliferation of electronics assembly, the tug‑of‑war between offshoring and reshoring, and a new calculus for what work stays human. The robots have not taken over so much as settled in, recalibrating prices, expectations, and borders. Their next act, informed by perception and simulation, will test whether factories can become as reconfigurable as software—able to pivot with demand spikes, climate constraints, and geopolitical shocks. What began as a cage for machines now looks more like a stage where people and robots rehearse a future of shared precision.

On a midnight shift, the factory sounds like rain inside: the patter of parts trays, the hiss of pneumatics, the whir of servomotors accelerating into arcs and pauses. The orange arm at station seven repeats its ballet—reach, grip, insert—never flinching when a new operator takes the post beside it. If the scene feels timeless, it isn’t. Within living memory, this choreography did not exist.

In the early 1960s, a General Motors die‑casting line welcomed an ungainly newcomer called Unimate, a programmable arm that tolerated heat, fumes, and tedium better than any human. Its presence announced a bargain: let the machine babysit the hazards, and we will keep the human for the parts that don’t fit templates. The momentum since then has been relentless and strangely quiet, like cement curing. Fences gave way to laser scanners, and clattering relays to whispering servos.

Robots that once required thick manuals and specialists now learn tasks from a hand pushed gently along a path. Grippers swap fingers mid‑shift; mobile platforms ferry bins between cells; overhead cameras tell arms where to pounce. A patch pushed overnight teaches a fleet a new assembly step. The factory of the near future looks less like a frozen cathedral of jigs and more like a stage set that can be struck and rebuilt by software—workcells re‑scripted by demand without tearing out the floor.

The first act belonged to inventors who treated the arm like a machine tool that could be taught. George Devol’s patent for a programmable article transfer system and Joseph Engelberger’s hustle turned an idea into Unimation, selling industry on repeatability where human fatigue introduced error. Early robots were caged for good reason; power without perception is a blunt instrument. Yet the automotive world embraced that bluntness with gusto, because nothing else could spot‑weld a chassis with such stamina.

As electronics and control systems matured, six‑axis designs from European and Japanese firms—ABB, KUKA, FANUC, Yaskawa—made the arm more wrist than club. The promise hardened into practice: better throughput, fewer rejects, consistent quality during lunch breaks and night shifts. Then the electronics boom altered the rhythm. Car plants cared about force; circuit boards demanded finesse.

The SCARA architecture—selectively compliant but lightning fast in the plane—taught robots to live inside clean rooms, pick components the size of punctuation, and dance across conveyors without losing their place in the music. Vision systems crept in, first as expensive, temperamental gadgets, then as indispensable eyes. The rise of consumer devices, from camcorders to smartphones, stacked assembly like origami; factories multiplied wherever supply chains could feed them, and robots slipped into repetitive touchpoints that punished human wrists. It was not a takeover so much as an invisible metronome syncing continents to the tick of global demand.

Safety fences began to soften in the 2000s with a simple proposition: what if the arm gave before the bone did? Collaborative robots arrived with rounded edges and torque limits, designed to stop when bumped and to be taught by hand rather than keyboard. Universal Robots popularized the idea; others added their own spins. A start‑up tried wide‑eyed, expressive machines meant to reassure and instruct.

A standard, ISO/TS 15066, mapped how close steel could work to skin. The effect was cultural as much as technical: small and mid‑sized factories that never hired a controls engineer suddenly found themselves mounting a cobot to a workbench and teaching it to take over a 3 p.m. slog. The skill ceiling lowered without dumbing down the work.

Perception changed everything twice. The first time, cameras helped arms find parts that weren’t exactly where a CAD model said they would be. The second time, machine learning gave those cameras a way to cope with clutter, glare, and the unhinged mess of real bins. What was once the white whale of factory robotics—reliable bin picking—came within reach thanks to depth sensors, convolutional networks, and faster edge processors tucked quietly inside control cabinets.

Force‑torque sensors and compliant wrists let robots feel their way into press‑fits. Simulation made practice cheap: engineers rehearsed line changes in digital twins, randomized textures and lighting so models wouldn’t be fooled on the floor, then pushed code that lived anywhere from a ruggedized PC to a cloud hockey rink. Open ecosystems, from ROS‑Industrial to vendor SDKs, turned factories into software playgrounds where integration stopped being a bespoke art. Supply chains do not forgive rigidity, and the shocks of the last decade made that painfully obvious.

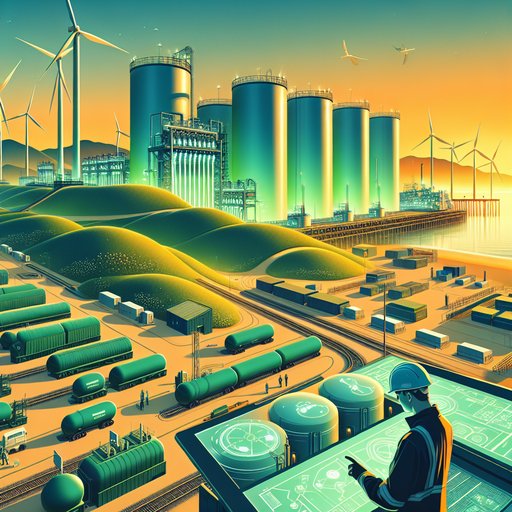

Earthquakes, pandemics, and canal blockages taught operations managers that efficiency without flexibility is just fragility with better branding. Robots became a hedge. Fixed arms learned to work with autonomous mobile platforms that threaded between cells like patient couriers, letting layouts breathe. Additive processes sidled next to machining centers to print fixtures on demand.

When travel paused, commissioning teams stared into cameras, teleoperating grippers half a world away. Some plants ran in the dark by design, others simply dimmed and kept going, supervisors watching dashboards that showed utilization graphs rather than footprints on a catwalk. Nearshoring entered the conversation not as a patriotic slogan but a probability calculation: if a reconfigurable line can pivot from Product A to B in days, geography matters less than latency—of logistics, of data, of response. The global ledger reflects those choices.

The densest clusters of robots sit in East Asia and parts of Europe, where automotive and electronics built cultures of automation. Countries that invested early kept a surprising amount of manufacturing even as wages rose, using robots as a bulwark against the gravity of low‑cost labor. Elsewhere, greenfield factories now skip directly to flexible automation, leasing robots as easily as forklifts, paying monthly for throughput rather than capital. The labor story resists slogans.

Repetitive injuries fall where robots take the heat, yet subcontracting and temporary work creep in at the edges as schedules tighten and niches multiply. The best outcomes follow training: technicians cross‑skilled from operator to programmer, maintenance crews retooled as diagnosticians, unions negotiating not just wages but reskilling pipelines and data transparency so a machine’s logs don’t become a cudgel. What comes next already peeks through the curtains. Dexterous grippers with tactile skins turn crumpled bags and flexible gaskets from headaches into solvable problems.

Soft actuators settle around odd shapes without crushing them. Large language models, wired into planners and motion libraries, let a line lead describe a task in plain speech and watch a robot suggest a work sequence, simulate it, and request the missing jig. Program by demonstration grows up: show an arm a handful of variations, and it generalizes, catching the drift rather than memorizing a pose. Preventive maintenance moves from calendars to predictions; a gearbox whispers trouble before a breakdown.

The dream is not a humanoid on a stool but a factory that senses itself, where machines explain their reasoning and improvement becomes a conversation. Still, the hardest problems are less mechanical than political and ethical. Who owns the data trail that a robot leaves in its wake—the torque traces, video frames, and cycle counts that reveal process secrets? How do we certify safety when perception systems are probabilistic and continuously learning?

Standards bodies inch forward; regulators try to keep pace without calcifying innovation. Nations compete with subsidies for domestic robot makers and chip fabs, while smaller economies wonder if the ladder of industrialization has been pulled up or simply rebuilt with new rungs. The geography of work will be redrawn not just by costs but by confidence: where skills, suppliers, and software coalesce into an ecosystem that can absorb shocks without cracking. Walk the floor and you can feel both truths at once: the serenity of machines that do exactly what they said they would, and the restlessness of an industry that knows certainty is a luxury.

Industrial robots did not erase the human from manufacturing; they changed the shape of human attention. Fewer hands, more eyes. Less lifting, more listening—to sensors, to forecasts, to whispers from the line. Whether that is a story of displacement or dignity depends on choices that are still ours to make.

The hum at midnight is steady, but it is not a lullaby. It is a question: how adaptable can we make the places where our physical world is assembled, and who gets to steer that adaptability? The first caged arms bargained for our safety. The next generation will bargain for our trust.

If we grant it, the reward may be factories that feel less like walls and more like instruments—tuned, responsive, and inclusive. If we don’t, the risk is not obsolescence so much as brittleness. Either way, the choreography continues, and the beat is getting faster.