The evolution of battery technology reads like a throughline from curiosity to critical infrastructure, and it is reshaping how the world uses renewable energy. What began with experimental cells in the 19th century now anchors gigawatt-scale projects that steady wind- and solar-rich grids, soak up surplus generation, and power homes through storms. Along the way, costs plunged, chemistries diversified, software matured, and pioneering installations proved that storage can move from the periphery to the center of the energy system. This is the story of a technology that learned to serve not just devices and cars, but entire economies—and of the breakthrough projects that made it real.

Electricity systems were designed around steady, dispatchable plants, but modern grids must welcome fluctuating wind and solar while keeping the lights on. Storage closes the timing gap between when the sun shines and when people need power, translating variable generation into dependable supply. It also makes renewable energy more valuable by preventing curtailment, absorbing fast frequency swings, and relieving congestion on transmission lines. In the face of climate targets and extreme weather, the ability to shift megawatt-hours across hours or days has become as important as adding new megawatts.

Batteries travelled a long road to this moment. Gaston Planté’s lead–acid cell in 1859 enabled the first rechargeable storage, followed by nickel-based chemistries and, much later, lithium-ion’s leap from the lab to commercial markets. Work by Stanley Whittingham, John Goodenough, and Akira Yoshino—recognized by the 2019 Nobel Prize in Chemistry—unlocked high-energy, rechargeable lithium-ion cells that spread from camcorders to smartphones and electric vehicles. As factories scaled and chemistries like lithium iron phosphate (LFP) matured, the same technology began stepping into substations and power plants, reconfigured for durability, safety, and rapid response.

Economics tipped the balance. According to widely cited industry tracking, average lithium-ion pack prices fell by roughly an order of magnitude between 2010 and 2023, reaching well under $150 per kilowatt-hour as manufacturing expanded and supply chains diversified. Simultaneously, system integrators learned to bundle batteries with power electronics and software that deliver multiple grid services from the same asset. LFP chemistries, which avoid cobalt and emphasize long cycle life and thermal stability, surged for stationary projects, while nickel-rich cells targeted applications demanding high energy density.

The result is that storage now pencils out not just for demonstration but for everyday grid work—peaking, firming, and frequency control. South Australia’s Hornsdale Power Reserve offered a first global proof at scale. Commissioned in 2017 at 100 MW/129 MWh and expanded to 150 MW/194 MWh, the project demonstrated that batteries could arrest frequency deviations in fractions of a second and reduce reliance on gas-fired reserves. Market data in its early years showed sharp reductions in the cost of frequency-control services, and the asset has repeatedly stabilized the grid during disturbances.

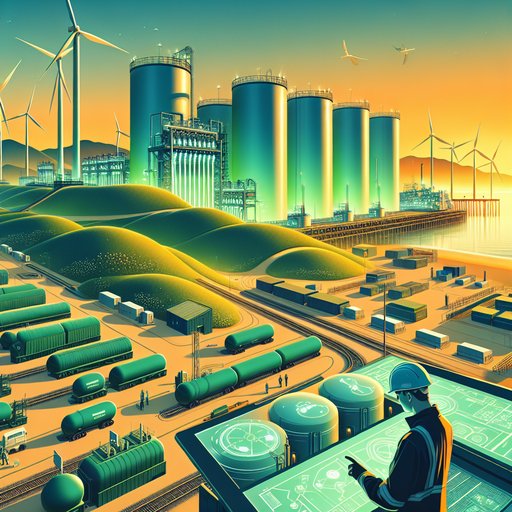

By responding instantly and monetizing multiple services, Hornsdale set a template for the business case and for regulatory reforms that recognize fast-acting inverter-based resources. California then turned the template into a fleet. The state crossed 10,000 MW of battery capacity on its grid in 2024, and these systems routinely shift midday solar into the evening, flattening the steep ramp that used to strain the system. Vistra’s Moss Landing Energy Storage Facility, built at a coastal power station south of San Francisco, grew to 750 MW/3,000 MWh through successive phases and now performs peaking and reliability roles once reserved for gas plants.

Operators refined safety and operational protocols after thermal events in 2021–2022, illustrating that the learning curve includes engineering and procedural improvements alongside megawatts. The cumulative effect has been fewer curtailments, more flexible operations during heat waves, and a clearer path to higher solar and wind shares. Diversity of storage forms is extending the envelope. Pumped hydro remains the world’s workhorse, with the Bath County Pumped Storage Station in Virginia providing more than 24 GWh of storage and delivering bulk, long-duration shifting that complements batteries’ fast services.

New long-duration chemistries are joining in: China’s Dalian vanadium redox flow project brought its first 100 MW/400 MWh phase online in 2022, with plans to reach 200 MW/800 MWh, proving a design that decouples energy capacity from power and tolerates deep cycling. In the United Kingdom, projects like the 98 MW/196 MWh Pillswood battery near Hull have shown how fast storage can support a wind-heavy system and participate in National Grid ESO’s rapid-response markets. Together, these efforts widen the toolkit for grids that must ride through extended lulls and sudden ramps. Storage is not only big and centralized; it is also networked and local.

Utilities like Green Mountain Power in Vermont have aggregated thousands of residential batteries into virtual power plants that shave peaks, lower system costs, and keep households powered during storms. In South Australia, a growing virtual power plant has linked customer-sited systems to deliver grid services alongside utility-scale assets, demonstrating that distributed batteries can behave as a single, dispatchable resource. Software platforms forecast load, bid into markets, and coordinate charging so that behind-the-meter batteries align customer benefits with system needs. This bottom-up capacity complements large installations by pushing flexibility deep into distribution networks.

All of this progress rests on steady advances in materials, manufacturing, and market design. Cobalt content has fallen in many lithium-ion formulations, LFP has expanded rapidly in stationary storage and electric buses, and new sodium-ion products are being piloted to diversify raw material supply. Grid codes have evolved to accept and even prefer fast, accurate, inverter-based responses for frequency and voltage support. Policy has followed: in the United States, the 2022 Inflation Reduction Act extended investment tax credits to standalone storage, while regulators in multiple countries now require or incentivize storage alongside new solar and wind plants.

The combination of technology, policy, and market access has turned storage from a niche to a necessity. The arc of battery technology shows how innovation becomes infrastructure once it meets a clear system need. Large-scale storage now underwrites higher penetrations of wind and solar by aligning supply with demand, cushioning shocks, and extracting more value from every clean megawatt installed. Continued scale-up, prudent safety practices, and attention to responsible mining and recycling will determine how quickly the next stages arrive.

With pumped hydro, batteries, and emerging long-duration options working in concert, grids can be both cleaner and more resilient. The next chapter is practical rather than speculative: continue deploying proven solutions while maturing new ones where they fit. Projects like Hornsdale, Moss Landing, Bath County, Dalian, and Pillswood illustrate different roles and time scales that together form a balanced portfolio. As costs keep trending down and software deepens the stack of services, storage will quietly do what good infrastructure does: make the extraordinary feel routine.

That is how a two-century-old idea is helping unlock a modern, renewable electricity system.