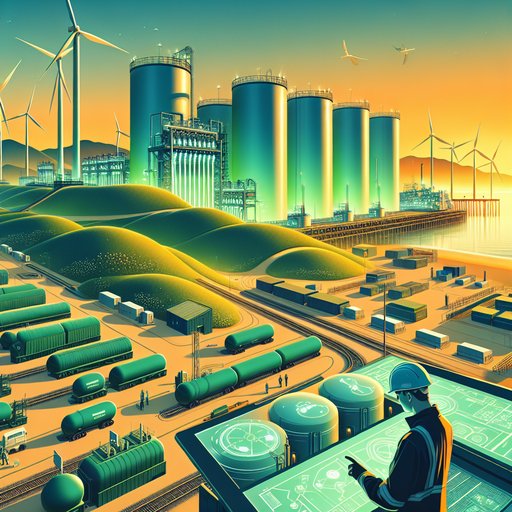

Electric power systems are being redesigned for a world where wind and solar play a leading role. This transformation goes far beyond adding turbines and panels; it requires new sensors, software, market rules, and hardware that can keep electricity reliable when supply varies with weather and demand shifts by the hour. Smart grid technologies—spanning advanced metering, real‑time control, and flexible demand—are turning passive networks into dynamic platforms. At the same time, operators are learning to integrate inverter‑based generation, large-scale storage, and responsive loads to preserve stability without relying on fossil plants. The result is a grid that is cleaner, more resilient, and increasingly digital, but one that also demands careful planning, cybersecurity, and investment to deliver affordable, dependable power.

Across the world’s coasts, engineers are turning the steady pulse of tides and the persistent motion of ocean waves into a new class of renewable power. Unlike wind and solar, the lunar clock governing tides is predictable decades in advance, and wave fields can be forecast days ahead, creating a resource that complements variable generation. From fast tidal streams in narrow channels to long-period swells rolling ashore, these technologies promise low-carbon electricity close to population centers that already cluster along coastlines. After years of prototypes, grid-connected pilots are now proving survivability, refining designs, and building the operational know-how needed to scale. The result is an emerging toolkit that can strengthen coastal energy systems, reduce diesel dependence on islands, and add resilience to decarbonizing grids.

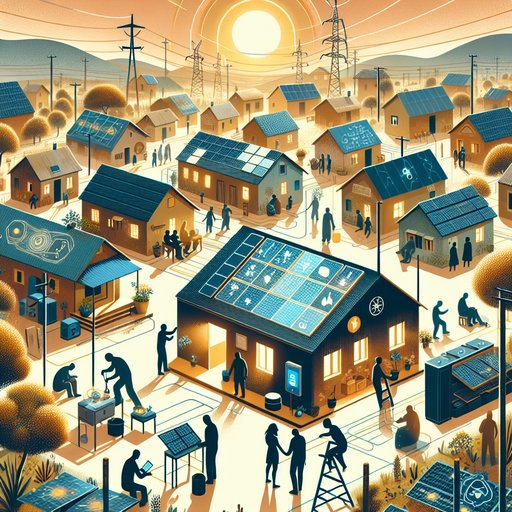

Expanding clean energy access to underserved communities is no longer a distant ambition; it is a practical pathway unfolding today through microgrids, pay‑as‑you‑go solar, and community energy projects. These approaches have emerged as powerful complements to national grids, which often struggle to reach remote or low-income areas with affordable, reliable power. Rapid declines in the cost of solar, batteries, and digital technologies, combined with innovations in finance and community ownership, are turning energy access into a viable, scalable service. By matching technology to local needs and aligning incentives for consumers, entrepreneurs, and utilities, these models deliver electricity that is cleaner, more resilient, and more inclusive. Their success is reshaping the conversation from charity to choice, investment, and long-term economic development.

Electric vehicles are quietly acquiring a second identity: mobile batteries that can feed electricity back to homes, businesses, and the wider grid. Vehicle-to-grid technology, enabled by bidirectional charging and smart software, allows parked EVs to supply power during peak demand, smooth volatility from renewables, and improve grid resilience. As electrification accelerates and renewable generation grows, this flexible storage—distributed across driveways and depots—offers a practical way to balance supply and demand without building entirely new power stations.