Linux is not one operating system but a family of distributions that shape the same kernel into different experiences. From Ubuntu’s emphasis on an approachable desktop to Arch’s bare‑bones starting point, each distro encodes a philosophy about simplicity, control, stability, and velocity. Those choices ripple outward through package managers, release models, security defaults, and hardware support, influencing how developers write software and how organizations run fleets at scale. Exploring this diversity reveals how a shared open‑source foundation can support both newcomers who want a predictable workstation and experts who want to design every detail, while continually pushing the state of the art in servers, cloud, and embedded systems.

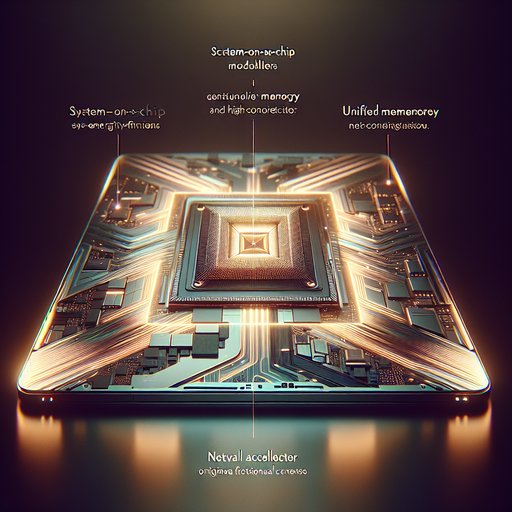

Measuring computer performance has never been a one-number affair, yet the industry has repeatedly tried to reduce it to a headline metric. Early eras prized MIPS and clock speed, then HPC crowned FLOPS, and now users compare gaming frame times, web responsiveness, and battery life. Each shift mirrors a deeper technological change: from single-core CPUs to heterogeneous systems, from local disks to cloud services, and from batch throughput to interactive latency. Understanding how and why benchmarks evolved reveals not only what computers do well, but also why traditional metrics often fail to predict real-world experience.

Formula 1’s broadcast journey mirrors the sport’s technological arc: from sporadic, grainy coverage to a global, data-rich experience that places fans virtually inside the cockpit. Over seven decades, innovations like onboard cameras, live telemetry, stabilized aerial shots, and interactive streaming have transformed how stories are told and races are understood. Today’s world feed blends engineering, cinematography, and real-time analytics to deepen comprehension of strategy and skill, inviting audiences to engage with the sport at an unprecedented level. Tracing that evolution reveals how broadcasting did more than show races; it reshaped the narrative of F1 and expanded its audience.

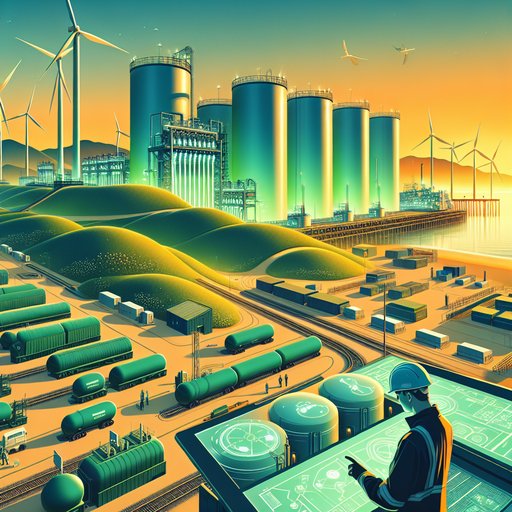

Across global supply chains, manufacturers are pairing meticulous energy efficiency measures with a rapid shift to renewable power, turning utility bills into a source of competitive advantage. Volatile fuel prices, tightening carbon policies, and customer demand for low‑carbon products have pushed energy from a back‑office expense to a board‑level priority. The response blends disciplined, data‑driven housekeeping with transformative changes to heat and power. From motors and steam systems to on‑site solar and long‑term power contracts for wind, the toolkit is now practical, financeable, and widely proven. The result is a quieter revolution on factory floors: less waste, lower costs, and falling emissions without sacrificing output or quality.