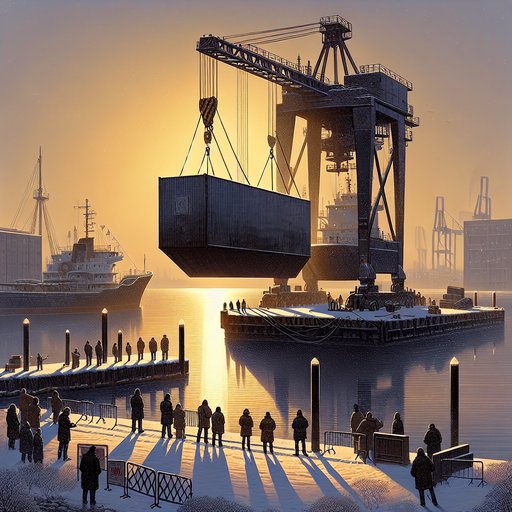

In a winter port where diesel exhaust hangs like a second sky, a crane lowers a corrugated box onto the dock and a crowd gathers at a polite distance. The box is not a reactor, not yet—just a full-scale mock-up, a placeholder for a class of machines that their makers say will finally make nuclear power something you can move, fence, and finance like industrial equipment. Microreactors, along with their slightly bigger cousins in the small modular reactor family, are inching from drawing boards into test pads and campus plans. Their promise is as prosaic as it is radical: reliable heat and power, anywhere people consent to host it. But consent is the operative word, and the next few years will hinge less on raw engineering than on the choreography between ambition, anxiety, and the rules that referee both.

The dockworkers try not to stare at the yellow trefoil stenciled on the side, a symbol meant as much for education as caution. Inside, there’s nothing radioactive—foam, steel ribs, a demo control console—but the future often arrives as stagecraft before it shows up as a utility bill. A woman in a parka runs her hand along the rivets, asking where the heat exchanger would go. The company rep points to where a chimney might rise, a stack no higher than the nearby ferry terminal.

It’s a traveling exhibit that has toured trade shows and stakeholder meetings, gathering signatures and questions in equal measure. The box looks mundane on purpose. The magic, the rep says, would be under the hood: fuel that can withstand heat spikes, control systems that fail safely, a core small enough to ship instead of pour. Three time zones away, the fluorescent lights in a campus auditorium flicker on as a dozen faculty and a few hundred students settle in.

A university in the Midwest has invited engineers to explain what a microreactor would mean for its labs, its budget, its neighbors. A biologist wonders about waste. An economist asks about the price of steam. The facilities manager worries out loud about the diesel tanks he fills every week to cover winter peaks and summer brownouts.

On the stage, a model the size of a heater sits under a camera feed, a scale stand-in for a design with a power rating that reads like a typo: single digits of megawatts. Enough to keep a campus humming, enough high-temperature heat to drive a turbine and warm research greenhouses, small enough to fit in the space behind the rec center. Not far from a Midwestern river, in a factory where the air smells faintly of new plastic and machine oil, a different ritual plays out. Clear-walled bins of ceramic beads glide past operators in hairnets.

Each is a capsule built to imprison whatever happens inside it—tiny, layered fuel particles that have been tested until they crack only under conditions most reactors will never see. On a workstation monitor, a dashboard nags about a familiar bottleneck: enriched fuel that’s higher than legacy reactors use but a far cry from weapons-grade. Supplies are growing, a domestic pilot plant started deliveries last year and more contracts are being let, but the curve still bites. The people in the factory don’t build reactors.

They build trust in materials, one pebble at a time, so when the rest of the stack is ready, the core ingredient isn’t the reason to slow down. Out in the Idaho desert, the wind pushes dust low across a pad poured to exacting specs, and a white trailer hums with the sound of laptops and forced air. This is where the government rehearses the future it wants for its far-flung bases: replace fuel convoys with a craft that can be craned into place, started once, and checked by a crew with more laptops than wrenches. The military case is straightforward in a way that civic life rarely is—security, logistics, resilience—and so the first real customers might wear camouflage.

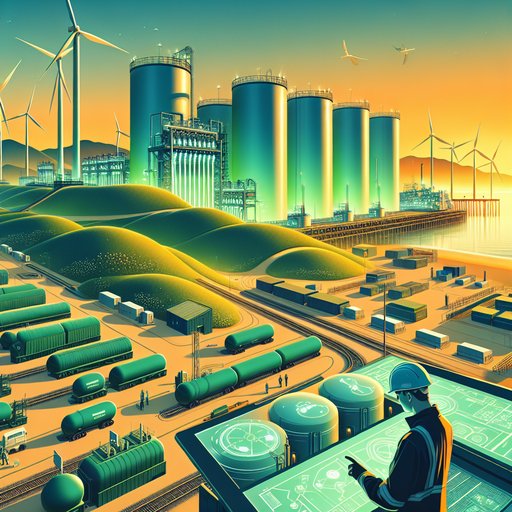

Their testbed sits within sight of older experimental buildings, relics from a time when the country built bigger to learn faster. Today, the bet is that small and standardized will let learning happen quickly without dragging the public appetite into the red. Back in a downtown conference room where the carpet is too soft for so many hard shoes, a start-up CEO is pitching not electrons but temperature. Her slides skip past kilowatts to focus on kilns at a ceramics plant, the condenser towers at a data center, the deep vats that keep a biotech line sterile.

Heat-as-a-service, she says, like cloud computing for thermodynamics. The bundle is electricity plus process heat plus a staffed operating contract, all packaged in a rate the customer can predict longer than a gas futures chart will stay legible. She doesn’t promise cheap—she promises certain, and she promises near. The next slide shows a container the height of a shipping truck beside a row of generators the client already owns.

The CFO cracks a smile: a hedge that doesn’t need a pipeline or a miracle battery. In a glassy office block two miles away, the regulator’s binders tell a different story: margin notes in a draft rule that tries to square old law with new shapes. The reviewers talk about risk-informed pathways and passive safety, about letting reactors that can survive themselves prove it without pretending they’re identical to the behemoths that came before. They also circle a problem that can’t be solved by cleverly engineered fuel or software that can diagnose a fault faster than a human: trust.

Trust that what leaves a reactor years later has somewhere to go; trust that the surrounding community sees benefits worth naming; trust that “modular” doesn’t become a way to ship complexity from one place to another. Canada’s regulator has already hosted joint technical reviews with peers. The U.S. is sketching a fresh playbook in pencil, erasing often.

On a Thursday night news segment, the anchor shifts from a wildfire map to a clip of a lab shot through with lasers. The audience has learned to recognize these images: a hohlraum glowing, a token asterisk noting that the whole machine still uses more power than it makes even if the tiny pellet inside does not. Tokamaks flash; a voiceover mentions a European lab’s final record-setting pulse before decommissioning; a startup shows a pizza-oven-sized device with coils tight enough to pass for sculpture. Fusion keeps pulling focus, with good reason—few ideas are cleaner on paper—but the camera cuts away before the commercial, promising an update in the next decade.

In the meantime, the fission crowd is setting up shop. Their case is not to eclipse fusion, but to prove a timeline that plays better with climate math and the rhythm of permits. On an island that imports fuel the way it imports everything else, the school custodian times his round to the regular hiccup of the diesel generators. He knows the beat well enough to jog a hallway before the lights flutter.

When the power co-op hosts a briefing about a microreactor, half the room brings calculators and the other half brings stories about winds that take roofs and ferries that don’t come for days. A fisherman asks whether the device needs water the way the old plant up the coast once did. The vendor shows a diagram with air-cooling fins, a heat plume that rises like the steam from the cannery. Someone else asks who guards it.

The co-op lawyer says a fence, cameras, a contract with the sheriff, and a security plan that they can’t detail there. It isn’t enough and it isn’t nothing. A data center executive visits the port and sees in the steel mock-up something like a product. He walks around the footprint with the measured steps of someone who has drawn rectangles on land-use plans for a decade.

He thinks about the load shedding notices that have come more often each summer, the grid interconnection queue that turns his timeline into a joke, the way his customers stare when he talks about “sustainably scaling.” He doesn’t want to own a reactor; he wants to lease a box and have someone else carry the regulatory headache, a contract that outlasts his next three server generations. In his mind’s eye, you can see the checklist form. It all fits, and yet he pauses at a question that has nothing to do with the pad: will the neighbors who oppose his cooling towers and fiber huts turn out for this too, and what would he owe them if they did? There’s a temptation, in a story like this, to skip to the end, to imagine a neat row of units that sleepwalk through winters and call back a new kind of grid into being.

The people doing the work don’t talk that way. They talk about siting in verbs—listening, revising, pausing—because small doesn’t mean invisible and modular doesn’t mean inevitable. They talk about the materials they can prove, the fire they can contain, the contracts they can honor, the ways the footprint of risk can shrink without the footprint of responsibility shrinking with it. You can hear, if you stand in the right rooms, engineers rehearsing answers to questions they once thought were secondary: who gets the jobs, how to tell the story in a language that isn’t physics, what contingency plan you’d be proud to test.

What’s striking, after weeks of following the crate and the factory and the flightline, is how unglamorous it all feels, like building a water plant with better press. The atom’s second act might arrive as heat on a ledger and silence in a generator hall, not a lightbulb moment but the absence of a flicker. Somewhere between the lasers and the legislation, the country is deciding whether a power source you can park behind a gym belongs in the mix. If it does, the measure of success will be not just the first connection to a bus bar, but the confidence to renew the contract when the first one is up, and the patience to admit that even small machines ask big questions before they hum.