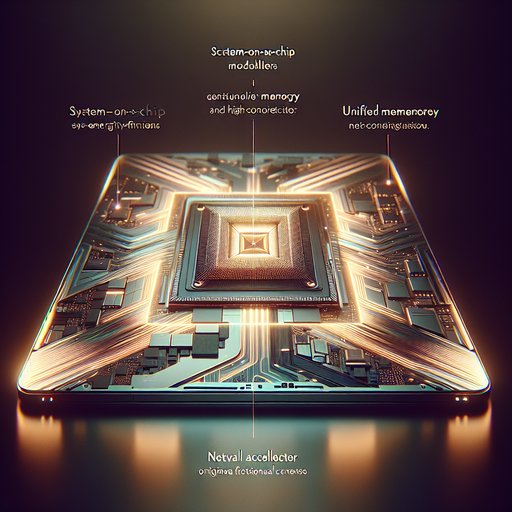

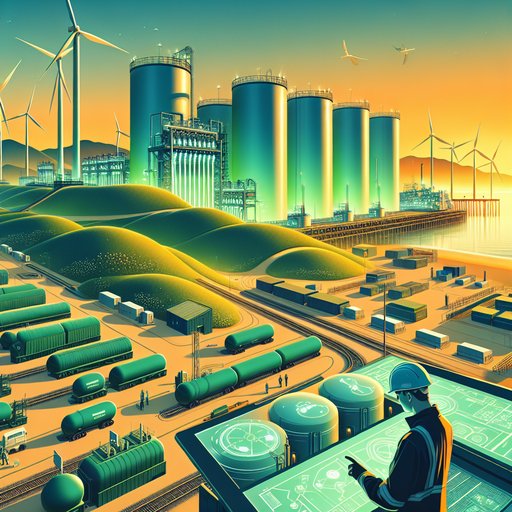

Global supply chains are experiencing strategic shifts as major companies adjust their logistics operations and inventory management approaches. Apple is reportedly stockpiling components for upcoming product launches, while traditional retailers are consolidating their distribution infrastructure in response to changing market conditions. Meanwhile, vulnerabilities in critical mineral supply chains are drawing attention from government officials concerned about national security and industrial resilience. These developments reflect broader transformations in how companies manage their supply networks amid evolving technological and economic pressures.

Apple is building up inventory for its first foldable iPhone in preparation for the device's launch next year, according to recent reports. The tech giant's decision to [1] represents a proactive approach to supply chain management, ensuring sufficient component availability for what is expected to be a significant product release. This inventory strategy suggests Apple is taking steps to avoid potential shortages that have affected the technology sector in recent years.

In the retail sector, distribution networks are undergoing significant restructuring. Macy's announced plans to shutter a unit at its Connecticut distribution center, with [2] as the retailer advances a turnaround effort that includes a multi-year strategy to optimize operations. The move reflects broader trends in retail logistics as companies reassess their physical footprints and distribution strategies in response to changing consumer behaviors and economic pressures.

Critical mineral supply chains are facing scrutiny from U.S. officials concerned about vulnerabilities in strategic resources. A rare earth metal called samarium, used in defense applications and cancer treatments, has been [3]. This designation highlights concerns about dependencies on foreign sources for materials essential to national security and healthcare, prompting discussions about supply chain resilience and domestic production capabilities.

The global industrial supply chain and economic landscape are undergoing a rapid, technology-driven transformation, according to industry observers. [4] that companies are increasingly leveraging advanced technologies and data analytics to optimize their logistics operations and respond to market dynamics. These technological innovations are enabling more agile and responsive supply chain management, though they also introduce new complexities and security considerations that organizations must navigate.