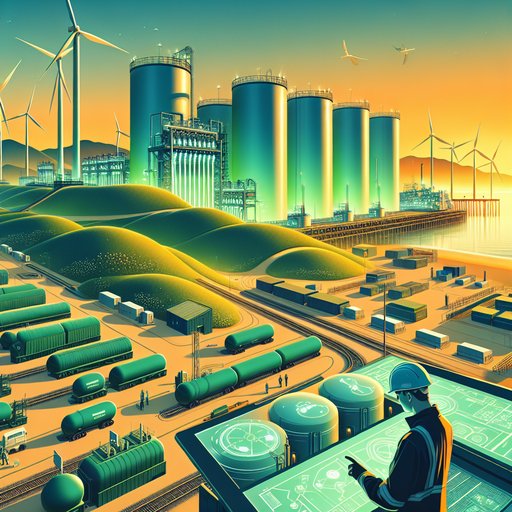

The global supply chain landscape is undergoing significant transformation, with major developments in the chemical industry and port infrastructure reshaping international trade patterns. Chemical manufacturers are pioneering new approaches to supply chain resilience, while strategic investments in Asian port facilities signal growing confidence in the region's logistics capabilities [1].

Chemical companies worldwide are actively diversifying their supply bases in response to recent disruptions and evolving market demands. Industry leaders are investing heavily in research and development to create more flexible and resilient supply networks, with a particular focus on developing alternative sourcing strategies and implementing advanced manufacturing technologies [1].

In Southeast Asia, significant developments in port infrastructure are enhancing regional logistics capabilities. MMC Ports, a major player in Malaysian maritime infrastructure, has received approval for an initial public offering (IPO), marking a milestone for the company that operates five of Malaysia's largest ports. Their flagship facility, the Port of Tanjung Pelepas, stands as a testament to the region's growing importance in global shipping networks [2].

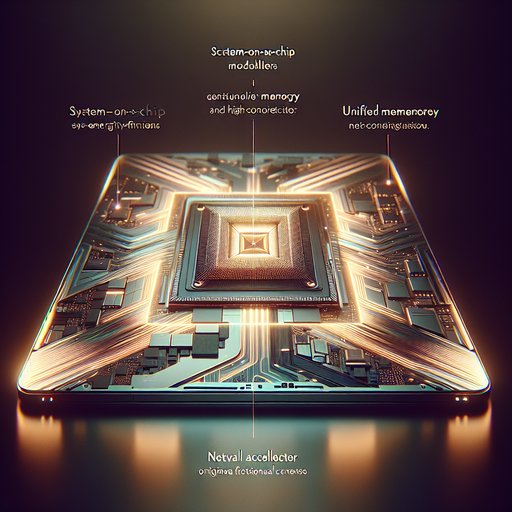

The technology sector is also experiencing supply chain innovations, particularly in display technology manufacturing. Supply chain reports indicate that advanced display technology production is being scaled up to meet increasing demand from major technology companies, suggesting improved coordination between manufacturers and end-users [3].

In response to growing supply chain security concerns, technology platforms are implementing stricter security measures. GitHub's recent announcement of mandatory two-factor authentication and short-lived tokens represents a broader trend toward strengthening supply chain security in the digital realm [4].