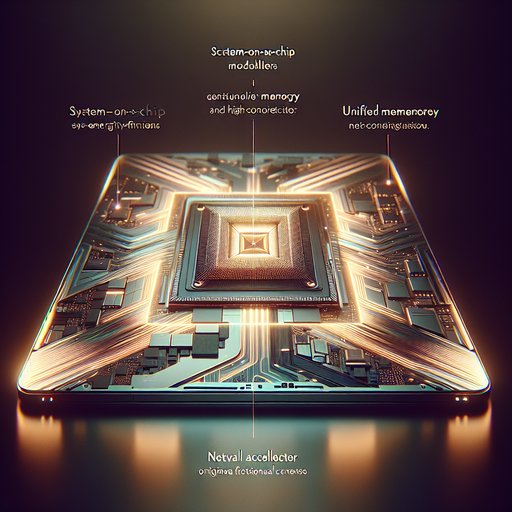

The semiconductor industry is witnessing a series of transformative developments as leading companies leverage new technologies to drive innovation, efficiency, and growth. On July 23, 2025, some of the world’s most prominent players—including Taiwan Semiconductor Manufacturing Co. (TSMC), Nikon, and Synopsys—announced advancements poised to shape the future of chip design and production. These breakthroughs span next-generation lithography tools, expanded production capacities, and AI-driven chip manufacturing, reflecting broader optimism about the sector’s potential amid soaring demand for artificial intelligence and advanced electronics.

Taiwan Semiconductor Manufacturing Co. (TSMC) achieved a historic milestone by joining the trillion-dollar market capitalization club, making it the first Asian semiconductor company to do so. This surge in value reflects unprecedented investor confidence, fueled largely by soaring demand for AI chips and advanced semiconductors. TSMC's dominant position in the high-end foundry market, particularly as industries worldwide race to develop and deploy AI-powered solutions, underscores both the resilience and innovation at the industry's core [1].

On the manufacturing front, Nikon announced it has begun accepting orders for its Digital Lithography System DSP-100, a tool capable of handling 600×600 mm substrates designed for advanced artificial intelligence silicon. This significant substrate size enables chip designers to fabricate larger and more powerful AI processors, potentially increasing throughput and computational performance. By enhancing back-end packaging and scalability, Nikon’s innovation offers chipmakers a crucial edge in addressing the insatiable global appetite for sophisticated AI hardware [2].

Meanwhile, the strategic push toward AI-driven chip design received another boost as Synopsys announced deeper collaboration with Tata Electronics to establish the world’s first AI-based chip foundry in India. This initiative positions India as an emerging force in the global semiconductor ecosystem, leveraging local engineering talent and advanced digital design tools. By integrating artificial intelligence at the foundry level, the industry aims to unlock greater manufacturing efficiency, optimize chip architectures, and respond swiftly to evolving market demands [3].

These technological and strategic advances are reinforced by ongoing improvements in manufacturing yields, with China’s SMIC achieving yields of 60 to 70 percent on its 5nm process—according to recent reports. Such milestones suggest increased capacity and maturity among global foundries, enabling a more robust and diverse supply chain. As next-generation materials and processing equipment become more widely adopted across the industry, the semiconductor sector is better positioned than ever to support breakthroughs in computing, connectivity, and intelligence [4].

- TSMC Joins Trillion-Dollar Club on Optimism Over AI Demand

- Nikon Introduces 600×600 mm Substrates for Advanced AI Silicon

- Synopsys strengthens India's role with push for world's first AI-based chip foundry

- SMIC’s Current 5nm Yields Rumored To Be In The 60-70 Percent Range, Making It An Exceptional Milestone To Pursue Sub-7nm Wafer Production, But Not Everyone Agrees With These Claims