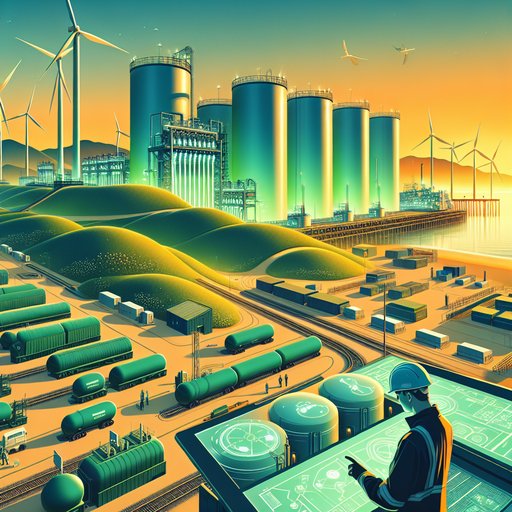

The printer hums like a polite appliance, but what it deposits is anything but ordinary: layers of living cells, coaxed into the geometry of a future organ. Across town, a team tunes genetic circuits the way coders tweak software, teaching microbes to sense, decide, and heal. Organ printing and synthetic biology slip from headline to routine, not with a bang but with the flicker of LEDs and the slosh of bioinks. The promise is intimate and planetary at once—replacing a failing kidney, filtering a polluted river—while the risks feel both distant and underfoot. In fluorescent labs and public meetings, the new logic of life is negotiated: who designs it, who owns it, and who agrees to live with it. The answers rarely fit into a press release.

They arrived as sparks behind safety fences—obedient arms doing the dirty work nobody missed—and then kept learning. From the first programmable manipulators to today’s camera‑guided, AI‑assisted cobots, industrial robots have evolved from brute repetition to adaptable collaborators. In their rise is the story of global manufacturing’s last half‑century: the consolidation of car plants, the proliferation of electronics assembly, the tug‑of‑war between offshoring and reshoring, and a new calculus for what work stays human. The robots have not taken over so much as settled in, recalibrating prices, expectations, and borders. Their next act, informed by perception and simulation, will test whether factories can become as reconfigurable as software—able to pivot with demand spikes, climate constraints, and geopolitical shocks. What began as a cage for machines now looks more like a stage where people and robots rehearse a future of shared precision.

In the muddy aftermath of the Woodstock Music & Art Fair in August 1969, Jimi Hendrix stepped before a thinned, awe-struck crowd with a white Fender Stratocaster and transformed a familiar anthem into a searing mirror of the times. His rendition of the Star-Spangled Banner, rendered through the Strat’s tremolo, feedback, and single-coil bite, carried the sounds of jets and explosions that many associated with the Vietnam War. In that moment, a mass-produced instrument built for working musicians became more than wood and wire; it became a vessel for dissent and identity. The Strat had already shaped rock, but at Woodstock it crossed into civic life, turning a stage into a public square and a guitar into a generational banner.

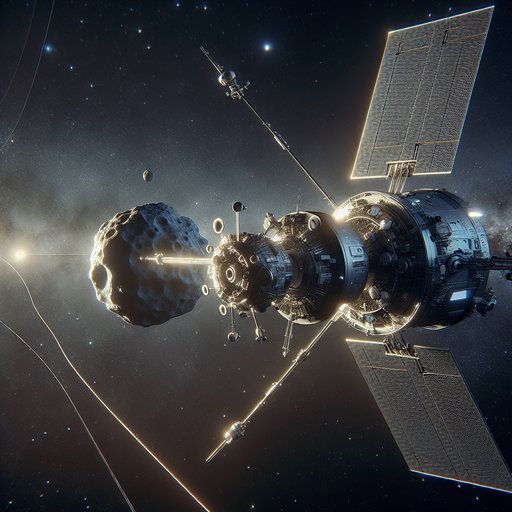

Remove buoyancy, sedimentation, and natural convection, and physics—and biology—behave in surprising ways. That is the premise behind zero-gravity research on platforms such as the International Space Station (ISS), drop towers, parabolic flights, and suborbital rockets. Over the past two decades, this weightless laboratory has enabled experiments that are hard or impossible on Earth, from quantum gases that linger longer to flames that burn without a visible glow. The results are reshaping textbook assumptions, informing spacecraft engineering, and seeding practical advances in medicine and manufacturing. As new facilities come online and commercial stations take shape, microgravity is evolving from a novelty into a precision tool for discovery.